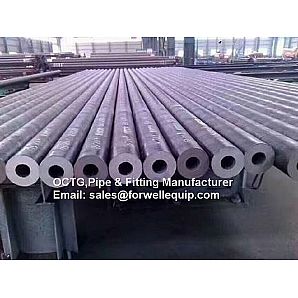

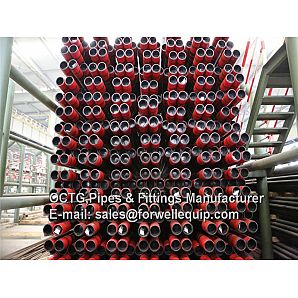

Recently, the successful trial rolling of Φ 193.68 × 8.33mm 13Cr stainless steel casing by 258 unit of rolling plant has filled the blank of the company's production of this specification of stainless steel casing, and further consolidated the company's industry leading advantage in the production of stainless steel seamless pipe.

13Cr casing is a kind of high alloy steel pipe.The wall thickness of main products ranges from 9 mm to 10 mm. The wall thickness of this specification product is relatively thin, so it is difficult to control the production organization and quality process. In order to ensure the smooth trial rolling, the hot rolling operation area of 258 unit successfully rolled a new 13Cr stainless steel tube with diameter of 193.68 × 8.33mm by consulting the production data of similar specifications in history, discussing various situations and difficulties that may be encountered in the production process in detail, formulating a strict production plan, adopting measures such as optimizing the delivery time and temperature, etc. The successful rolling of this new product has improved the batch production capacity of stainless steel casing of 258 unit, laid a solid foundation for the subsequent production of Φ 193.68 × 8.33mm L80-13cr casing for international users and Φ 193.68 × 9.52mm L80-13cr casing for domestic key users,and further improved the market competitiveness of the company's products.